Rubber Compounds for Hose

The company designs and produces various specifications of chlorinated polyethylene outer rubber for hydraulic hose in accordance with the SAEJ517, GB/T3683 and GB/T10544 standards, which can replace CR, EPDM, CSM and NBR/PVC and has good processing performance and excellent resistance to aging, low/high temperature, ozone, UV and oil.

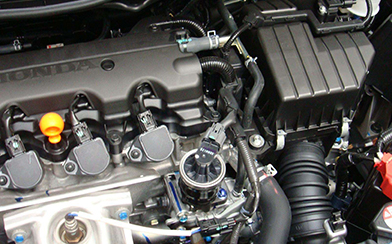

The various specifications of chlorinated polyethylene (CPE) inner and outer rubber designed and manufactured for turbocharger hose according to the GB/T33381 standard can replace CR, EPDM, ACM, and AEM rubber and has good processing performance and excellent resistance to aging, low/high temperature, ozone and oil.